BLADE CHARACTERISTICS

BLADE SELECTION = SUBSTANCE + SURFACE + SOLVENT

Scraperite blades have been developed using various engineered materials to meet an ever broadening range of use cases defined by our customers. Each blade could potentially be used on any surface, however, the solvents or chemicals used to clean the unwanted substance may destroy the blade or the underlying surface. The range of blade options ensures the right selection to match the surface being cleaned with the solvent used to remove the unwanted substance.

- No collecting germs

Blades naturally lift dirt up and away without picking up germs and can be easily wiped with a disposable cloth after each stroke, unlike scrubbing pads and sponges that collect dirt with every pass. Scraperite safety scrapers are much better at scraping targeted areas, on soft surfaces where metal blades or scrubbing pads would damage a wider area of the underlying surface.

- Low risk of property damage

- Low risk of injury

They offer added safety by reducing risk of injury by laceration and risk of property damage. Combined with the curved blade, it becomes our safest scraper combination yet. The curved blade allows the user to create a rotating or circular motion with the wrist to more easily lift things stickers off.

- non conductive

- non magnetic

- non corrosive non sparking*

SOLVENT RESISTANCE

| ACETIC ACID 10% | ||||

| ACETONE | ||||

| ALCOHOL: ISOPROPYL | ||||

| AMMONIA | ||||

| BENZENE | ||||

| BLEACH 15% | ||||

| CITRIC ACID | ||||

| DISH SOAP | ||||

| FORMALDEHYDE 40% | ||||

| FORMIC ACID 3% | ||||

| HYDROFLUORIC ACID 4% | ||||

| LYE | ||||

| METHYL ETHYL KETONE (MEK) | ||||

| NITRIC ACID 0.1% | ||||

| SULFURIC ACID 5% | ||||

| TURPENTINE | ||||

| VINEGAR | ||||

| XYLENE |

EDGE CHARACTERISTICS

| EDGE HARDNESS | SOFT | MED | HARD | MED |

| PLIABILITY | SOFT | SOFT | RIGID | MED |

| ABRASIVENESS | LOW | MED | HIGH | MED |

MATERIAL DECOMPOSITION

Plastics break down under various conditions and the same characteristics that make them ideal can also affect their durability. Since chemicals have the most impact on material decomposition, the use case should always be considered to ensure both surface will not be damaged and blades will not decompose.

EDGE WEAR

Blades are designed with optimal scraping angle and edge sharpness. Edge sharpness is reduced with every stroke as the blade passes over the surface and becomes less effective in direct correlation with roughness of surface and hardness of substance being removed. Scraperite safety scraper blade compositions help define Blade Characteristics which have obvious and direct impacts on the performance, like temperature and chemical resistance. Aside from these factors, direct edge to surface friction wear could be correlated to the human fingernail and the varieties of hardness that develop naturally.

COMPARED TO A FINGERNAIL

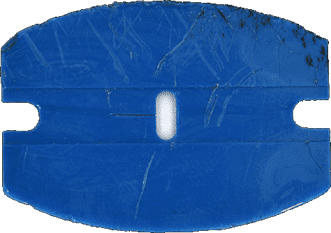

- Scraping it against concrete, aside from pain, will probably gouge it like the barnacles did to the blades in the images below.

- Scraping against a countertop or table, it would would probably handle the unpleasant job.

These blades were used to scrape barnacles from a 46' Beneteau.

SURFACE CONSIDERATIONS

| DELICATE OR SOFT | |

| UNEVEN OR WAVY | |

| HARD FLAT | |

| UNEVEN OR ROUGH FINISH |

USE TEMPERATURE RANGES

| MINIMUM (°C/°F) | -50/-58 | -40/-40 | -40/-40 | -40/-40 |

| MAXIMUM (°C/°F) | 65/149 | 118/246 | 49/120 | 80/176 |

BLADE COMPOSITIONS - THE RIGHT SAFETY SCRAPER FOR THE JOB

GENERAL PURPOSE ORANGE - GPO

The Orange General Purpose safety scraper blade is a forgiving material soft enough to be used on most soft surfaces like other plastics, thanks to its natural lubricity and pliability. It also has good resistance to household and industrial chemicals making a great all-around blade for general use around the home or workplace. Ideal for use on wood furniture and flooring, LCD displays, glass stovetops and stone countertops, and many other soft surfaces found around us in every day life. This resistance to chemicals makes it ideal for removing decals with chemicals like acetone used to quickly break down the acrylic adhesives. This material is approved by Alcoa and Boeing for use on aircraft alloys.

![]() Recycling Code 7 - bring these back for commercial recycling. They'll get ground up, melted, and made into something else.

Recycling Code 7 - bring these back for commercial recycling. They'll get ground up, melted, and made into something else.

MEDIUM BLUE - MBL/PCB

These blades are tough. The polycarbonate base compound is similar to the materials used to make bulletproof partitions seen banks and guard booths. The Blade Characteristics page shows other differences of value including resistance to bleach and chlorine, making it ideal for use for pool and spa maintenance. These safety scraper blades provide a balance of pliability and strength, conforming to curves and rough surfaces with slightly better resistance to edge wear than the Orange blade. Good on ceramics and stone as well as laminates and vinyl. Blue blades are tough enough for use in boat maintenance above and below the waterline including handling tough barnacle scraping without damaging the anti-fouling paint. This are the PCB polycarbonate blue Scraperite blades slightly reengineered for better performance.

![]() Recycling Code 7 - bring these back for commercial recycling. They'll get ground up, melted, and made into something else.

Recycling Code 7 - bring these back for commercial recycling. They'll get ground up, melted, and made into something else.

HARD YELLOW - HYL/ACY

This blade is made of a hard and more brittle material and is the most rigid. Its low flexibility keeps it flat when removing stubborn substances from hard flat surfaces such as glass or tile but is more prone to breakage under vertical pressure. This characteristic also increases edge durability under similar circumstances compared with other blades. Solvent must be carefully selected to ensure blade material will not break down.

![]() Recycling Code 7 - bring these back for commercial recycling. They'll get ground up, melted, and made into something else.

Recycling Code 7 - bring these back for commercial recycling. They'll get ground up, melted, and made into something else.

BLACK INDUSTRIAL - BIN

The Black Industrial blades is an advanced engineered material ideal for trade professionals. Made of a highly durable chemical resistant compound, this blade offers a durable edge with high break strength yet flexible enough to conform to curved surfaces. Ideal for use where there is a lower risk of scratching the underlying surface and substance being removed requires heavy pressure. Similar to the Orange compound, it is suitable for use with chemicals used to remove RTV, other sealants, and pressure sensitive adhesive found in tape and stickers.

![]() Recycling Code PA - bring these back for commercial recycling. They'll get ground up, melted, and made into something else.

Recycling Code PA - bring these back for commercial recycling. They'll get ground up, melted, and made into something else.

RECYCLE RESPONSIBLY - DON'T RELY ON THE SORTING CENTER

At Scraperite, we try our best to meet our social and ecological responsibility to keep plastics from polluting our planet more than it already suffers. Plastics have become part of our lives and serve a definite purpose and solution for products and resulting services. It is everyone's responsibility to start by thinking about their first action when disposing of any plastic, and when purchasing disposable products like Scraperite safety scrapers.

-

All Scraperite plastic safety scraper blades contain around 20% recycled industrial plastic regrind

-

We hope Scraperite holders will be purchased once and stay in the toolbox as keepers and rather than be thrown away.

-

Don't rely on the recycling center to pick the right bin for you. Put used blades back into the original pack or keep them in a separate container and bring them back to a Scraperite Official Reseller. It's probably far better for us to cover costs of getting blades to right recycling partner, rather than rely on proper disposal at sorting centers.

*Some low level static electricity can build up in certain situations, it is recommended to use proper precautions and perform independent testing before handling, and using the blades on sensitive electronics like avionics or circuit boards. They are generally accepted for use in the oil and gas industry, all while maintaining industry and jobsite safety guidelines. Galvanic corrosion is also of low concern if blades are replaced before each use on dissimilar metals or surfaces.

See Types and Specifications page

Find an Official Reseller portal and find a Dealer near you