Safety First: How to Protect Yourself While Scraping Surfaces

Scraping may seem like a low-risk task, but if you’ve ever slipped and scratched a surface—or worse, yourself—you know it’s worth taking seriously. Whether you're prepping a boat hull, removing caulk from an RV skylight, or cleaning residue off glass, the right tools and precautions can make all the difference.

One of the smartest safety upgrades? Using a plastic scraper instead of a metal one. Plastic blades are already a safer choice, reducing the risk of injury and surface damage without sacrificing effectiveness.

Here’s how to make surface prep safer and smarter from start to finish.

-

Wear the Right Gloves for the Job

Even when using a plastic blade, your hands are doing the heavy lifting. Protect them with gloves that match your task:

-

Chemical-resistant nitrile gloves are great when you're working with caulk removers or adhesive solvents.

-

Padded work gloves help when scraping old finishes or stuck-on gunk from hard surfaces like wood or metal.

-

Thin, dexterous gloves are useful for delicate scraping—like on glass, painted surfaces, or vinyl decals—where control matters more than brute strength.

Plastic scrapers reduce the likelihood of injury compared to metal, but a good pair of gloves still goes a long way toward keeping hands safe and comfortable.

-

Use Eye Protection for Debris and Chemicals

Plastic scrapers are less likely to gouge or send chips flying than metal ones, but there's still a risk, especially when dealing with brittle materials, old caulk, or dried sealants.

-

Wear safety glasses or goggles when working above your head, removing stubborn buildup, or using chemicals.

-

Eye protection is especially important in enclosed areas, like RV bathrooms or boat cabins, where splatter or fumes can quickly become an issue.

The softer edge of a plastic blade gives you more control and less unexpected snapping, but visibility is still key to preventing injuries.

-

Watch Your Blade Direction and Hand Placement

Accidents often happen when people scrape toward themselves or don’t pay attention to where their free hand is. Always scrape away from your body and keep your other hand well out of the blade’s path.

Plastic blades make this safer. They’re flexible and less likely to slip dramatically or cut deeply, but improper technique can still cause strain or minor injury. Use steady, even pressure rather than forceful jabs. If you're straining to make progress, reassess: the angle, blade condition, or technique might need adjusting.

-

Work in a Well-Ventilated Area

Plastic blades are often used in combo with solvents or adhesive removers. These chemicals can release strong fumes, especially in confined spaces.

-

Open windows and doors, or work outdoors when possible.

-

Use fans to improve airflow, or wear a respirator designed for VOCs if you’re in a closed area.

-

Always read the safety information on any product you’re using alongside your scraper.

Plastic blades don’t generate sparks or rust, and they’re chemically resistant, making them a safer match when working with strong cleaners or solvents.

-

Choose the Right Blade for the Surface

One of the most overlooked safety tips? Use the right blade for your job.

Metal scrapers might feel heavy-duty, but they can easily scratch delicate finishes, gouge painted surfaces, or damage vinyl. Plastic scrapers are:

-

Gentler by design, offering effective scraping without digging in.

-

Less likely to slip or chip surfaces, especially important for boats, cars, or glass.

-

Chemically compatible with most cleaning and prep agents, making them safe to pair with whatever’s in your maintenance kit.

Different jobs call for different blade strengths and flexibilities, so match your scraper material to the task. This is not just for better results, but also to avoid accidents and costly damage. Visit our blade compositions page to choose the right blade for you.

-

Dispose of Used Blades Safely

Even plastic blades get dull or worn out over time. When you're done with one, don’t toss it loosely into the trash—wrap it in tape or store it in a designated container to prevent accidental cuts.

Better yet, recycle it. Many plastic scraper blades are made from recyclable materials. If your local recycling program accepts rigid plastics, check to see if your used blades qualify. By recycling instead of tossing, you reduce waste while still staying safe.

For mobile crews or regular maintenance work, consider keeping a small, sealable container for used blades that you can empty into your recycling bin later.

Wrap-Up: Make the Safer Switch

Metal scrapers might have their place in heavy-duty construction, but for most maintenance, cleaning, and prep work, plastic scrapers offer a safer, more versatile option. They’re less likely to cause injury, damage the surfaces you’re working on, or react badly with chemicals.

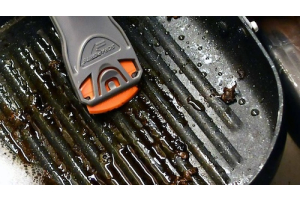

If you’re looking for a reliable plastic scraper that balances safety and performance, Scraperite offers a range of blade types suited for every kind of surface and material. Our orange blades are a great all-purpose option. They're pliable enough for delicate surfaces like paint, glass, and plastic, yet chemically resistant enough to pair with acetone or adhesive removers.

Whether you’re a pro tackling daily tasks or a DIYer gearing up for a project, choosing the right scraper—and using it safely—makes all the difference.